SAE/AISI 4130 1095 8620 1018 4140 1010 1045 6150 1020 1023 Steel Sheet Alloy Steel Plate Supply

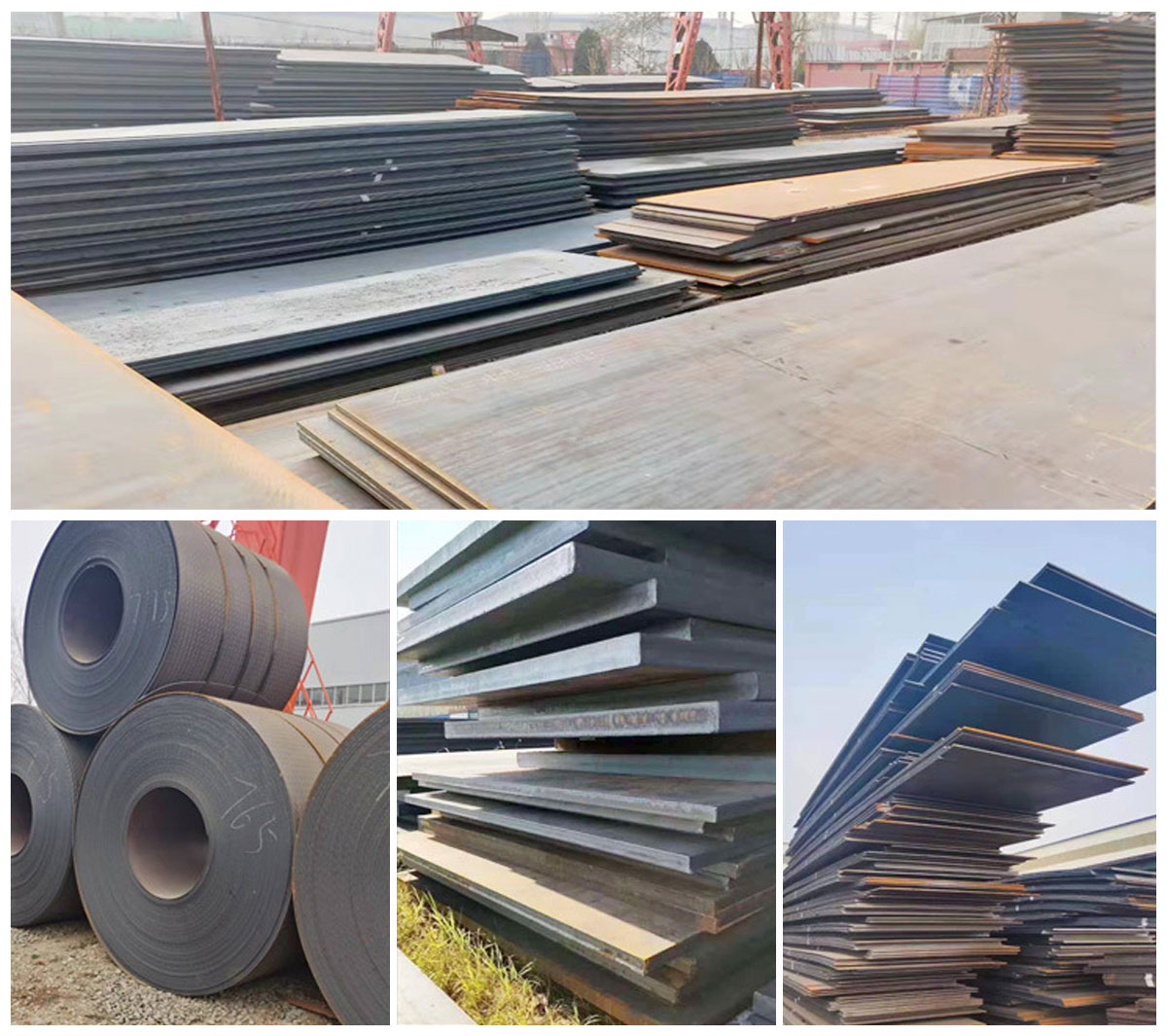

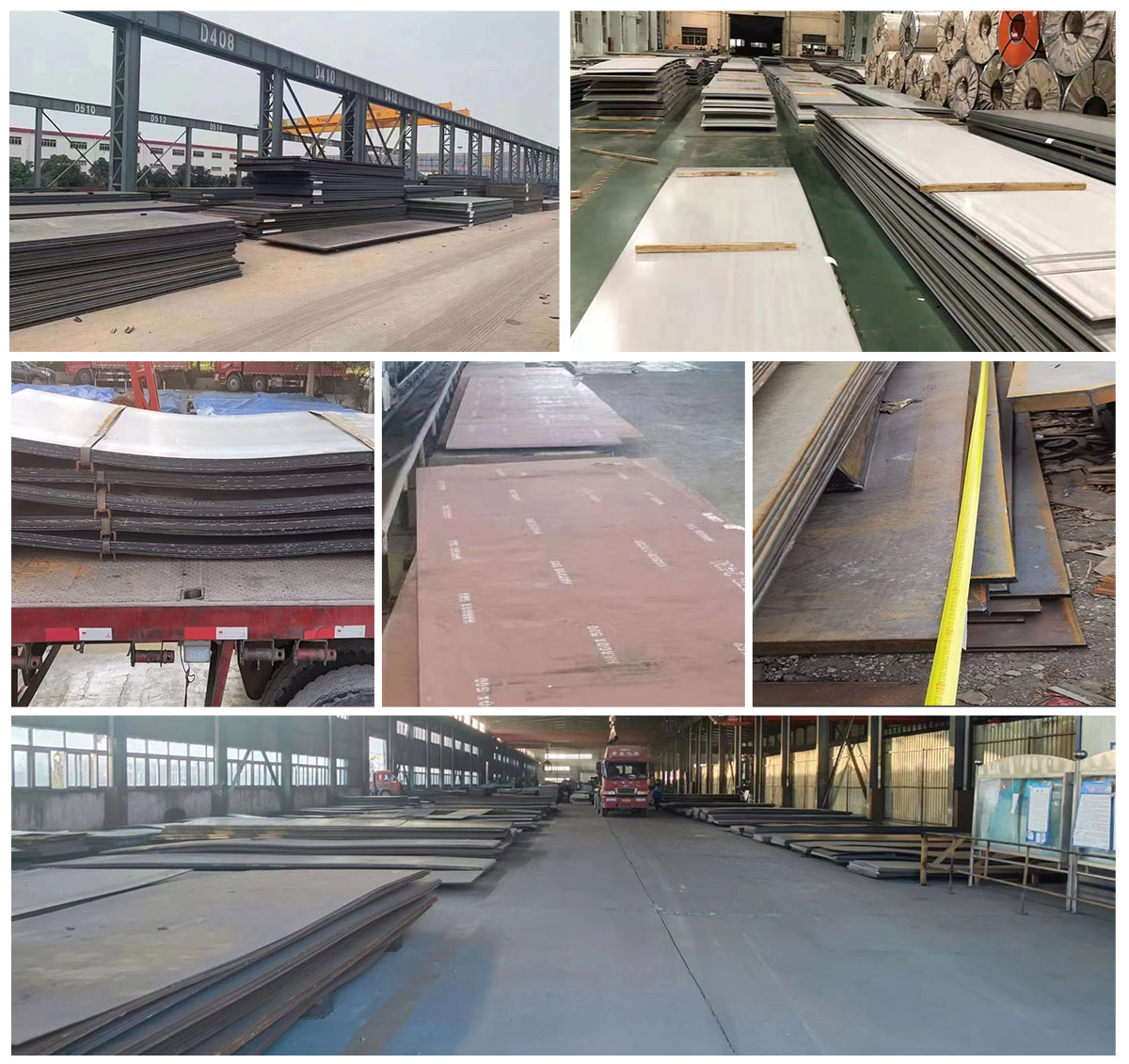

dingjian Steel specializes in the production of steel plates for equipment, steel plates for automobiles, steel plates for ships, steel plates for aerospace, steel plates for construction engineering, etc. Various alloy steel plates and carbon steel plates with excellent performance can be manufactured according to the standard.

1. The most competitive price

2. ISO certified excellent manufacturer

3. Third party inspection: SGS, CE, etc.

4. Sufficient inventory, Fast delivery.

PRODUCT CATEGORY

|

Steel Plat/Coils

|

Carbon Steel Plate Alloy Sheet/Coils

|

|

Width(mm)

|

600-25000mm

|

|

Thickness(mm)

|

0.2-400mm

|

|

Length(mm)

|

600-12000mm

|

|

Standard

|

AISI/SAE 4130, 1095, 8620, 1018, 4140, 1010, 1045, 6150, 1020, 1023, etc. |

|

Surface

|

Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE, checkered, perforation, etc.

|

|

Packaging

|

Standard export packaging. Can be packed according to customer requirements. |

|

Application

|

Shipbuilding, architectural engineering, mechanical equipment manufacturing, aerospace equipment manufacturing, petrochemical industry applications, precision device manufacturing, etc.

|

AISI – American Iron and Steel Institute Standard.

In the AISI standard, the representation methods of carbon steel and alloy steel grades are basically the same. Most of them are represented by four Arabic numerals, and letters are added occasionally in the middle or at the end. For example: 1005, 94B15, 3140, etc. The first two digits in the four digits indicate the type of steel and the content of the main alloying elements. The last two digits represent the value of the average carbon content of the steel in parts per ten thousand.

1. The first digit (or first and second digits) indicates the following category numbers: 1—carbon steel, 2—nickel steel, 3—nickel-chromium steel, 4—molybdenum steel, 5—chromium steel, 61—chromium Vanadium steel, 8 – low nickel chromium steel, 92 – silicon manganese steel, 93, 94, 97, 98 – chromium nickel molybdenum steel.

2. The second digit (the category number is two digits without this item) indicates the following steel types or alloy element content: Carbon steel: 0—general carbon steel, 1—free cutting steel, 3—manganese structural steel.

Molybdenum steel: 1 – chromium molybdenum steel, 3 and 7 – nickel chromium molybdenum steel, 6 and 8 – nickel molybdenum steel, 0, 4, 5 – molybdenum steel with different Mo content.

Nickel and nickel-chromium steel: the average nickel content is expressed as a percentage. Chromium steel: 0—lower chromium content, 1—higher chromium content.

Low-nickel-chromium steel: 6, 7, 8, and 1 mean that the content of nickel and chromium is certain, and the content of molybdenum is different. 6 represents a molybdenum content of 0.15 to 0.25, 7 represents a molybdenum content of 0.2 to 0.3, 8 represents a molybdenum content of 0.3 to 0.4, and 1 represents a molybdenum content of 0.08 to 0.15. 3. The third and fourth digits represent the average carbon content, expressed in ten thousandths. Some steel grades ert B or L in the middle: B—boron-containing steel, L—lead-containing steel.

When “H” is added at the end, it indicates a steel type that has certain requirements for hardenability. Some add the prefix “M” or “MT”: M—mechanical grade, MT—mechanical tubing.

相关产品

-

Wear Resistant Steel Plate

Hardoxs 450 550 500 600 Wear Resistant Steel From Swedish Steel Plate

阅读更多